Stockpile measurement refers to the process of determining the size, volume, or weight of a stockpile of materials. This technique is essential for businesses that handle bulk commodities, such as coal, minerals, aggregates, and fertilizers. These stockpiles are often found in dedicated storage areas, where they are built up through truck deliveries, bulldozer operations, and manual labor. The challenge for managers and workers is knowing exactly how much material they have on hand. In the past, this was done through estimation or basic GPS tools, which were not always reliable. Today, advanced technologies like drones, LiDAR, and photogrammetry allow companies to measure stockpiles with remarkable precision. This not only improves efficiency but also reduces costs and enhances safety across industries. Accurate stockpile measurements are crucial for businesses in various sectors. Whether it's coal, ores, fertilizers, or industrial dust, precise data helps companies manage inventory effectively, reduce waste, and improve profitability. Here are some key reasons why stockpile measurement matters: Manual estimations can lead to overstocking or understocking, both of which impact profits. With accurate measurements, companies can optimize inventory levels, avoid unnecessary costs, and make better decisions about when to restock or begin mining again. This level of precision also helps in planning maintenance schedules, managing workforce hours, and reducing downtime. Ultimately, accurate stockpile measurements contribute to higher productivity and better financial outcomes. With modern technology, stockpile data can be collected and analyzed to support strategic business decisions. Accurate measurements help in financial reporting, tax calculations, and securing loans or grants. The more precise the data, the easier it is to present to stakeholders, investors, or regulatory bodies. This transparency builds trust and ensures compliance with industry standards. Many industries are subject to strict regulations, especially those involving environmental emissions or material handling. For example, the EU Emissions Trading System requires businesses to track CO2 emissions accurately, which is made easier by precise stockpile management. Regulators appreciate clear and verifiable data, which makes it easier for companies to demonstrate compliance without guesswork or assumptions. Stockpile measurement can significantly reduce the risks associated with manual inspections. Workers no longer need to walk on unstable piles or enter hazardous environments, thanks to drone-based solutions. Using UAVs or robotic systems minimizes exposure to dangerous conditions, ensuring safer working environments. It also reduces the need for frequent site visits, saving time and resources. Below is a 3D fly-through of salt stockpiles at a mine, created using LiDAR data from the Elios 3 drone. This visualization showcases how modern technology can provide detailed insights into stockpile structures. Large stockpiles of dust, stone, or fertilizer can be unpredictable and dangerous for human workers. Drones eliminate these risks by providing accurate data without requiring physical access to the site. Additionally, efficient stockpile management reduces the need for emergency repairs and lowers long-term maintenance costs, further improving worker safety and operational efficiency. Stockpile measurement is widely used across several industries, including: Aggregates like sand, gravel, and crushed stone are essential in construction. Managing these materials requires precise stockpile measurements to ensure proper mixing and usage. Accurate measurements help prevent cross-contamination between different aggregate types and protect inventory from damage due to weather or erosion. Stockpile aggregates Construction companies rely on stockpile measurements to manage materials like sand, wood chips, and concrete. These measurements help plan hauling routes and optimize resource allocation. They also help drivers and operators know what to expect on-site, improving safety and reducing delays. Mining operations use stockpile measurements to track ore and mineral inventories with high accuracy. Drones equipped with LiDAR or photogrammetry sensors can safely measure large, complex stockpiles. In recycling and waste management, stockpile measurements help track the amount of material available for processing. This improves efficiency and ensures compliance with storage regulations. Ports and shipping centers deal with large volumes of bulk materials, making accurate stockpile measurements critical for logistics and supply chain management. There are several methods for measuring stockpiles, each with its own advantages and limitations. Here’s an overview of the most common approaches: Traditional manual methods, such as using a walking wheel or estimating by truckload, are still used in some cases. However, they are generally less accurate and more time-consuming compared to modern techniques. Smartphones can now serve as cost-effective tools for stockpile measurement. Apps like Stockpile Lite allow users to capture images and videos, then upload them for analysis. This method is fast and relatively affordable. Photogrammetry involves taking multiple photos and using software to create 3D models of stockpiles. This method is highly accurate but requires specialized equipment and expertise. LiDAR (Light Detection and Ranging) uses laser pulses to create precise 3D maps of stockpiles. It is known for its high accuracy, especially in low-light conditions. However, LiDAR equipment is expensive, and it typically requires trained professionals to operate. Drones are among the most effective tools for collecting stockpile data. They can carry cameras, LiDAR, or photogrammetry sensors, allowing for fast and accurate measurements. For indoor applications, drones like the Elios 3 are ideal. They can navigate dark and dusty environments, making them suitable for silos, tunnels, and other confined spaces. The Elios 3 has been successfully used in mining, cement, and construction sites. In one case, it measured stockpiles in a clinker silo, a challenging environment that traditional methods would struggle with. Another project involved monthly stockpile checks at a cement plant, where the drone completed surveys of 30 stockpiles in under two hours. For outdoor stockpiles, drones with long battery life and multiple payload capabilities are preferred. They can cover large areas quickly and efficiently, making them ideal for mines, construction sites, and ports. Drones equipped with LiDAR or photogrammetry sensors are revolutionizing how stockpiles are measured. These tools provide digital copies of stockpiles that can be used for reporting, communication, and tracking changes over time. The Elios 3, for instance, is transforming the way industries handle complex stockpile measurements. It enables faster, safer, and more accurate data collection, making it an essential part of modern industrial workflows. Galvanized Steel Ground Screw Pile Conventional size is 76*400*850 and the material is Q235 steel or Q355 steel.We can also customize according to the drawings you provide. galvanized steel ground screw pile,carbon steel ground pile,hot-dip galvanized ground screw,ground screw pile Shandong Great Steel Co.,Ltd , https://www.great-steel.comWhat is Stockpile Measurement?

Sulfur stockpile

Sulfur stockpileWhy Is Stockpile Measurement Important?

It Increases Profitability and Efficiency

It Provides Useful Data for Business Decisions

It Helps Meet Regulatory Requirements

It Enhances Workplace Safety

What Industries Use Stockpile Measurement?

Aggregates

Construction

Mining

Quarry mine stockpiles

Quarry mine stockpilesRecycling

Shipping and Ports

Stockpile measurement in shipping and ports

Stockpile measurement in shipping and portsStockpile Measurement Methods

Manual Methods

Traditional stockpile measurement with a walking wheel and tape measure

Traditional stockpile measurement with a walking wheel and tape measureSmartphone Applications

Stockpile Lite app

Stockpile Lite appPhotogrammetry

Drone footage on left, photogrammetry 3D model on right

Drone footage on left, photogrammetry 3D model on rightLiDAR

Drones for Stockpile Measurement

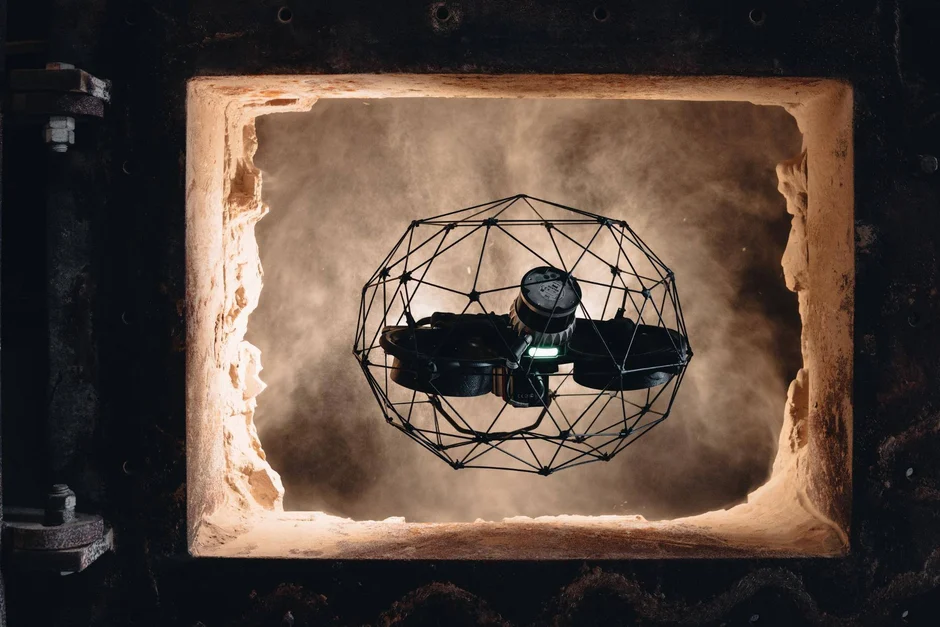

The Elios 3 entering an industrial asset for an inspectionÂ

The Elios 3 entering an industrial asset for an inspection BENEFITS OF DRONES FOR STOCKPILE MEASUREMENT

UPGRADING STOCKPILE MEASUREMENT TECHNIQUES THANKS TO DRONES