Safety The Elios 3 allows for safe and efficient access to the interior of wind turbine blades without requiring personnel to enter hazardous or confined spaces. This significantly reduces the risk of accidents and injuries during inspections. Speed Thanks to its advanced design, the Elios 3 can inspect up to four turbines in a single day—far surpassing traditional methods that typically handle only one or two per day. This efficiency cuts down on downtime and improves operational productivity. Cost Savings By identifying faults early, the Elios 3 helps avoid costly repairs or replacements. It's estimated that this technology can save over $1 million per blade by minimizing the need for expensive maintenance or full replacements. Access Wind turbines can be over 170 feet tall, making manual inspections both difficult and dangerous. The Elios 3 provides straightforward access to these towering structures, reducing human exposure to fall risks and improving overall safety. Wind energy has been a vital source of power for centuries, from ancient windmills to modern-day turbines. Today, it plays a significant role in global energy production. In 2022, wind energy accounted for 7.33% of the world’s electricity generation. However, wind turbines are complex machines, especially when it comes to their construction, transportation, and inspection. A single blade for a land-based turbine can exceed 170 feet in length, while the largest wind turbine in the world—the Goldwind GWH252-16MW—has a rotor diameter of over 827 feet. These massive dimensions make both installation and maintenance challenging, particularly when it comes to internal inspections. Traditionally, inspectors have faced significant risks when checking for cracks, damage, or issues like grease buildup inside turbine blades. Lightning strikes, in particular, can be dangerous if the protection systems are not properly configured. That’s where the Elios 3 steps in, offering a safer and more efficient way to inspect even the most challenging parts of a wind turbine. Pathfinder Optics, a company specializing in robotics and drone inspections, is using the Elios 3 to conduct high-quality inspections of some of the largest wind turbines in America. Their work highlights how modern drone technology is transforming the renewable energy sector. Joseph Valenzuela, Operations Manager at Pathfinder Optics, brings years of experience as a drone pilot and non-destructive testing technician to his work. He recognized the need for safer alternatives to high-risk inspections and founded Pathfinder Optics with that goal in mind. Today, the company uses a range of drones and robotics to serve multiple industries, with a growing focus on wind turbine inspections. Joseph relies heavily on the Elios 3, which offers both visual and LiDAR capabilities. These features allow him to collect detailed data quickly, giving his team a competitive edge. “The LiDAR and real-time video feed are game-changers,†he says. “They help us deliver more accurate and actionable insights.†Initially, Joseph used a standard rotary drone for turbine inspections, but found that the Elios 3 was far more suited for the task. Its protective cage makes it ideal for navigating tight spaces within the blades, while its advanced sensors provide critical data for each inspection. During a recent project, Joseph inspected four turbines in a single day. Each blade required careful navigation through the hub, and the Elios 3 made the process much more efficient. “I can now inspect four turbines in the time it used to take me to do just one,†he explains. One of the biggest challenges is access. Joseph often climbs ladders to reach the hub, carrying the drone with him. In some cases, the drone is winched up alongside him. The Elios 3’s compact size and portability make it an essential tool for these kinds of operations. Once inside the hub, Joseph navigates the drone through each blade, capturing high-resolution images and LiDAR data. Each flight lasts about 220 feet, and the drone returns to the hub before moving on to the next blade. After all inspections are complete, he carefully descends back to the ground. This method allows Joseph to inspect four turbines in a single day, a feat that would be nearly impossible with traditional techniques. Image right: The Elios 3 flies inside the turbine blades with ease, saving inspectors time and energy in cramped spaces. Joseph’s use of the Elios 3 enables detailed visual and LiDAR surveys that are crucial for monitoring the condition of wind turbines. While the control system (CMS) manages the pitch and rotation of the blades, it cannot detect internal damage caused by factors like lightning strikes or grease buildup. A single damaged blade can cost over $1 million to replace. Early detection through drone inspections helps prevent such losses. For example, if a lightning protection system is improperly installed, the blade could explode or catch fire during a strike. The Elios 3 helps identify these risks before they become catastrophic. During each inspection, Joseph uses the Elios 3 to detect manufacturing defects or potential hazards. He then reports these findings to the turbine owner or manager, who can take swift action to prevent further damage. This proactive approach saves money and avoids costly emergency repairs. Regular inspections are required for wind turbines, typically once or twice a year. Before drones, this meant sending workers into the blades—posing serious fall risks. Now, the Elios 3 eliminates this danger while also improving efficiency. Joseph can complete an entire inspection in under three hours, compared to half a day or more in the past. In addition, the Elios 3 is invaluable in emergency situations. If a turbine catches fire due to lightning or a grease leak, the drone can quickly assess the situation without putting anyone at risk. This rapid response capability is a major advantage in high-stakes scenarios. Joseph finds that the Elios 3 not only speeds up his workflow but also keeps him safe. “I’m not a fan of heights, and this drone lets me work efficiently without being exposed to unnecessary risks,†he says. “It allows me to stay in the safety of the hub while still completing thorough inspections.†Since starting with wind turbine inspections, Joseph has completed projects along the West Coast of the U.S. He knows that using the Elios 3 isn’t just safer—it also helps turbine owners save money and avoid costly damage from lightning strikes. All of this is possible thanks to the reliability and performance of the Elios 3 in even the most challenging environments. Discover more about the Elios 3 and its specialized LiDAR payload. All images in this article are credited to CLP Power. Variable valve timing (VVT) solenoid or oil control valve controls the oil flow according to the engine speed and load. VVT solenoid is a vital part of the variable valve timing system. 2010 Ford F150 Vct Solenoid,Vvt Solenoid Ford F150,Vvt Exhaust Solenoid,Intake Valve Timing Control Solenoid Wenzhou Zhongking Parts Co.,ltd , https://www.oemvvt.comSaving Over $1 Million: Wind Turbine Inspections With The Elios 3

Key Benefits at a Glance

Developing Drone Inspections For The Renewable Energy Industry

How Drones Can Be Used For Wind Turbine Inspections

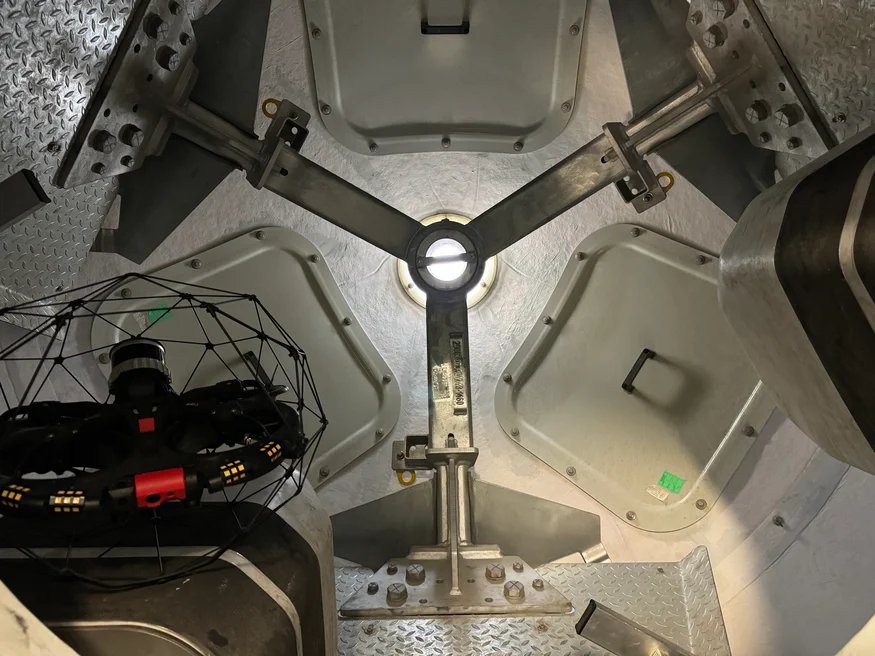

The small area from where Joseph can access the separate wind turbine blades

The small area from where Joseph can access the separate wind turbine blades

Benefits Of Using A Drone For Wind Turbine Inspections

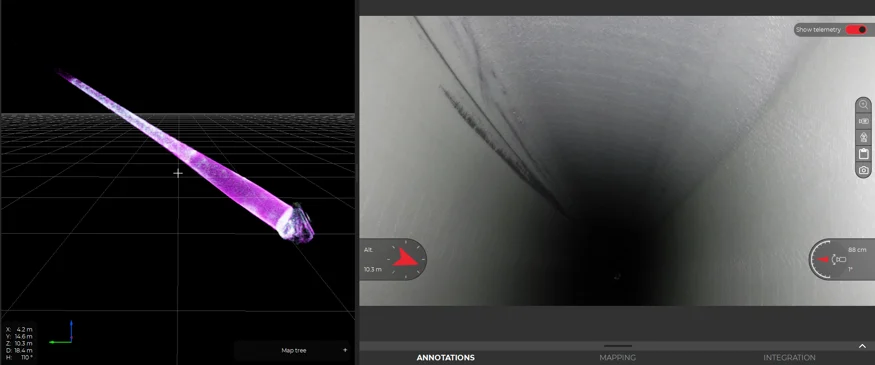

The interior of the wind turbine is clearly visualized with the Elios 3's LiDAR scan

The interior of the wind turbine is clearly visualized with the Elios 3's LiDAR scanBringing Modern Drone Technology To Renewable Energy

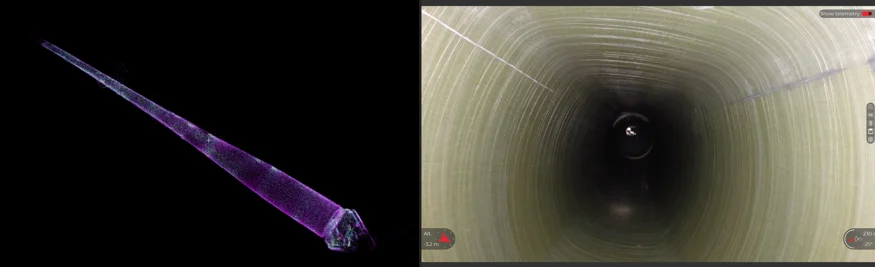

Joseph is conducting safer turbine inspections with the drone and working faster than ever

Joseph is conducting safer turbine inspections with the drone and working faster than ever

The Oil Control Valve (OCV) is a a critical part used in every engine that is fitted with variable valve technology (VVT). A single control valve will regulate the supply of oil to a designated VVT hub, to advance or retard the timing by altering the camshaft angle position. Controlled by the ECU, the OCV receives electrical signals, instructing it to adjust the oil flow as required, in accordance to current driving conditions.