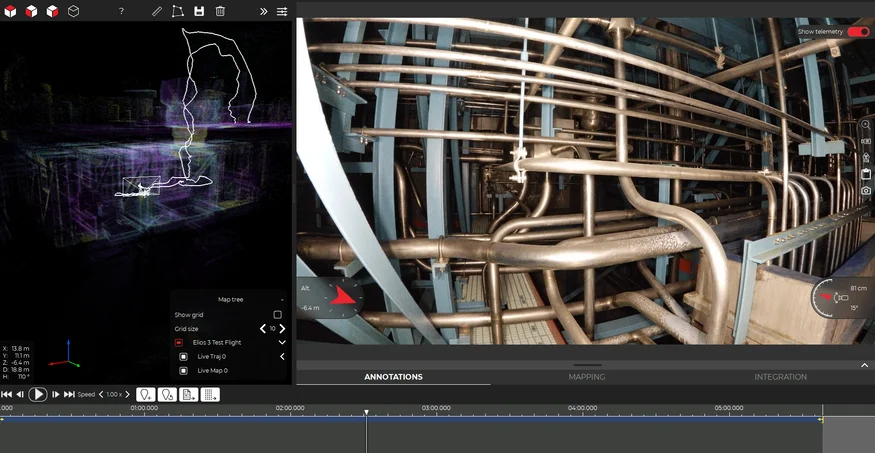

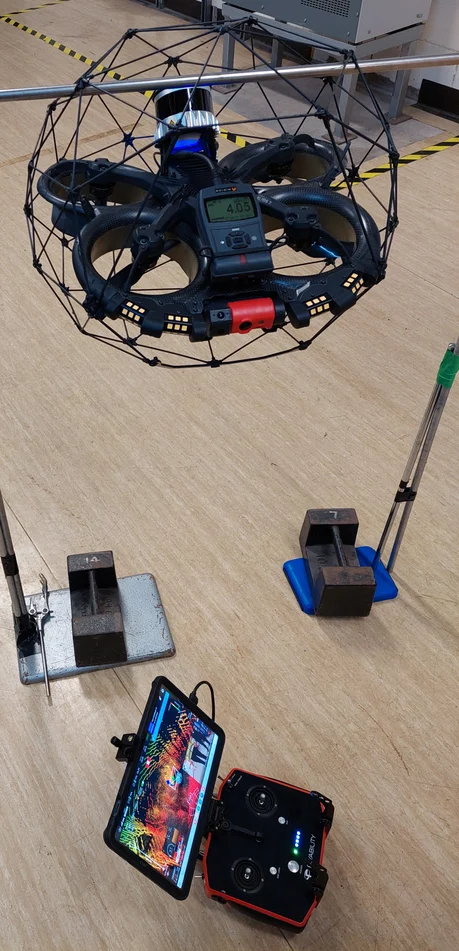

In this exclusive interview, we speak with Amanda Smith, the UAV equipment programme manager at Sellafield, to explore how drones are transforming safety and efficiency at one of the world’s most complex nuclear sites. Sellafield, once known as Windscale, is located on the Cumbrian coast in the UK. It was a functioning nuclear power plant until 2003 and now serves as the site of one of the largest and most complex decommissioning projects globally, expected to take several decades to complete. Amanda Smith, the lead of the UAV equipment programme at Sellafield, works within the Engineering and Maintenance Profession. This programme is part of the specialist equipment services, which supports a wide range of projects across the site, where over 3,500 staff are employed. She discusses the introduction of a UAV programme at Sellafield and how drones are being used to meet the site’s core objectives: working safer, faster, and more cost-effectively. I've been leading the UAV programme at Sellafield for about four years. Before that, I had no direct experience with drones. However, our team recognized the potential value drones could bring to the site. As an electrical engineer, it was a steep learning curve transitioning from no drone knowledge to building a comprehensive UAV programme. Today, we conduct regular flights and have integrated drones into our inspection processes. With new technologies, we're also exploring the use of drones for radiation detection in the future. Sellafield is like a small town—covering nearly six square kilometers. It has its own fire service, medical team, and multiple departments. It's one of 17 sites under the Nuclear Decommissioning Authority (NDA), a government initiative focused on cleaning up early UK nuclear sites. We share best practices and lessons learned with other NDA sites, such as Bradwell and Sizewell. Our team has even supported drone operations elsewhere, helping to spread awareness and improve industry standards. Our first drone tests were done through an external contractor who introduced us to the basics of drone operations. After evaluating the applications, we decided to create an in-house programme. It took six months to get clearance for our first flight due to strict safety protocols and approvals. Initially, we focused on security and resilience. By 2020, we expanded to over 200 asset inspections, and now we have a fleet of more than 20 drones operated by around 20 pilots. Screenshot from an inspection completed with an Elios drone at Sellafield As of 2023, I manage four equipment engineers who are also remote pilots. They are responsible for selecting, testing, and maintaining our drones. Once a drone is in the fleet, it undergoes regular maintenance checks every three, six, and twelve months. In addition, we have an Emergency Duty team that operates 24/7, including holidays. Annually, we conduct at least 200 flights with the core team alone. We started with external inspections but are now expanding into internal ones, using tools like LiDAR and 3D modeling. One of the main challenges we face is contamination. Unlike radiation, which can be measured and managed, contamination requires thorough decontamination of any equipment that enters a contaminated area. Loose radioactive dust is particularly problematic. While we can clean the exterior of a drone like the Elios, we can't access the internal components to ensure they’re free of contamination. So once a drone is deployed inside a contaminated space, it stays there. Additionally, flying drones in areas with significant loose contamination can disturb the dust, potentially exceeding regulatory limits. In such cases, we avoid using drones to prevent further contamination risks. The RAD payload is a specialized sensor mounted on the Elios 3, designed for remote radiation detection and localization. It uses the RDS-32WR sensor by Mirion Technologies. Our goal was to test the Elios 3 and RAD in a radiological survey workflow. We set up a controlled environment with sealed sources and dummy sources to avoid confirmation bias. A pilot flew the Elios 3 with the RAD payload and looked for radiation spikes to create a heat map. Amanda Smith along with representatives from Flyability and Coptrz This was a joint project involving our remote technologies group, radiometrics systems, and Flyability and Coptrz. The test was successful. The RAD detected elevated radiation levels and even identified a high-sealed source in a separate room. We plan to conduct more tests to refine flight techniques and understand how the sensor performs in different environments. The Elios 3 RAD includes an RDS-32WR sensor by Mirion Technologies (image courtesy of Coptrz) We already use Elios drones for a wide range of tasks. The RAD payload is especially exciting because it aligns with our strategic goals of improving safety, speed, and cost-efficiency. Safety: Drones allow us to send them into hazardous areas before humans enter, reducing risk. Speed: We can deploy quickly and gather data instantly. Cost: Using drones saves time and money compared to traditional methods like scaffolding. Before the RAD was introduced, we were already saving around £5 million per year by using UAVs instead of traditional methods. We use the Elios drones for internal inspections, such as checking pipe hangers that support critical infrastructure. Thanks to the Elios, we can visually inspect these assets and alert maintenance teams to any issues, reducing the risk of containment breaches. We also use the drones to inspect hard-to-reach structures like cranes, avoiding the need for scaffolding. The cage design of the Elios ensures safe operation close to assets without risking a crash. We're expanding our use cases beyond emergency responses to routine inspections. Every project we complete often sparks new ideas, opening up new opportunities for drone use. The modular system of the Elios 3 is promising. We're currently testing the RAD payload, but the LiDAR payload is already showing great potential. A recent LiDAR scan is being used to create a 3D-printed model of a specific site element. We continue to train our pilots to maximize the effectiveness of our drone operations. As we refine our flight techniques, we aim to make tasks safer, faster, and more efficient across the site. A big thank you to Amanda Smith and Tom Calverley for sharing their insights. Learn more about Sellafield on the UK Government website. Discover more about the Elios 3 and its applications PVC Sheet Pile, Vinyl Sheet Pile, Plastic Sheet Pile, Corrosion Resistant Sheet Pile Wuxi Qijing Machinery Technology Co., Ltd. , https://www.sinombbrmedia.comInterview: Elios Drones at Sellafield, Europe's Largest Nuclear Site

Tell Us About Your Background. Did You Work With Drones Prior To Starting The Sellafield UAV Program?

Tell Us About Sellafield - What Are You Doing There?

Amanda has been in charge of the UAV programme at Sellafield for about 4 yearsHow Would You Describe The Sellafield UAV Programme?

How Are You Using Drones In Radioactive Or Contaminated Environments? We've Heard About Radioactive Dust - Could You Tell Us More About That And What Challenges You Face?

You Have A Substantial Fleet Of Elios Drones From Flyability. This Year, We Launched The Elios 3 Drone Along With The RAD Payload Specifically For Use In The Energy Industry. In July 2023, You Had A Proof Of Concept For This Payload. What Was The Process?

What Are Your Thoughts On Working With Elios Drones In These Use Cases?

The Elios 3 RAD in testing at SellafieldSo, What's Next For Your Drone Fleet At Sellafield?