T BAILEY, INC. understands that choosing the right tank head can be quite a challenge. With numerous shapes and styles available, it’s essential to select the one that best suits your tank's requirements. Picking the correct tank head is critical for ensuring both the structural integrity and optimal performance of your tank.

In fact, the industry has developed a unique set of terms specifically for describing tank head characteristics, referred to as "Head Terminology." Familiarizing yourself with these terms can significantly aid you if you're looking to have a tank designed and manufactured. This article will break down the terminology to help you make an informed decision.

Understanding What a Tank Head Is

Before diving into the specifics, let’s first define what a tank head is. Simply put, a tank head is the top or bottom closure of a tank. It plays a crucial role in maintaining the tank's functionality and durability.Key Terms to Know

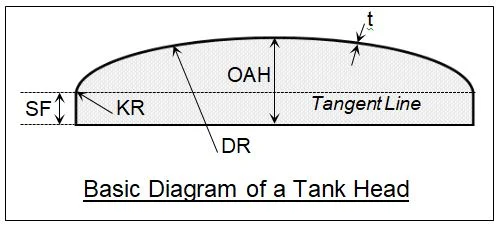

Here are some important terms related to tank heads: - **Dish Radius (DR):** Refers to the primary radius of the dome-shaped portion of the tank head. - **Knuckle Radius (KR):** Denotes the inner radius where the dome transitions into the flange. - **Straight Flange (SF):** The cylindrical part that connects the tank head to the tank wall. - **Tangent Line:** Marks the point where the knuckle meets the straight flange. - **Thickness (t):** The specified minimum thickness of the material used for the tank head. - **Overall Height (OAH):** Total external height of the tank head, including the thickness, dome height, and flange height. Role of Tank Heads

Tank heads serve several vital functions: 1. **Structural Integrity:** They maintain the tank's strength, even under extreme pressure from volatile substances or compression. 2. **Weather Resistance:** Tank heads must withstand harsh environmental conditions, such as severe weather. 3. **Temperature Resilience:** They should endure extreme temperatures, whether cryogenic or heated environments. 4. **Safety:** For tanks containing explosive or flammable materials, tank heads ensure the safety of both people and the surrounding area.Types of Tank Heads

Most tank heads conform to ASME standards or similar regulations, especially when used in pressurized gas storage or chemical reaction tanks. The type of tank head depends on its design features and intended application.#1. Elliptical or Semi-Elliptical Tank Heads

**Characteristics:** - These tank heads are cost-effective due to their relatively low height compared to the diameter. - Their radius varies between the major and minor axes, typically in a 2:1 ratio. **Applications:** - Ideal for non-fired pressure vessels like liquefied petroleum gas tanks and air receivers.#2. ASME Flanged and Dished Tank Heads

**Characteristics:** - These heads have a shorter profile while still providing pressure resistance. - Although they may require thicker materials than elliptical heads, they are more economical for atmospheric storage tanks. **Applications:** - Great for mixing tanks since the flatter radius allows mixers to be positioned lower in the tank.#3. Torispherical Tank Heads

**Characteristics:** - Features a flat dome with a spherical surface and a cylindrical edge connected by a transition section. - Stress distribution isn't as uniform as elliptical heads, but they are easier to fabricate. **Applications:** - Suitable for large-diameter pressure storage vessels.#4. Conical Tank Heads

**Characteristics:** - Shaped like a cone, tapering from the wide flange end to the narrow center. - Due to their geometry, they exert significant lateral thrust, requiring reinforcement. **Applications:** - Commonly used on vertical pressure vessels for collecting or draining substances. - Also employed to connect vessels of varying diameters.#5. Flat Tank Heads

**Characteristics:** - Generally less expensive as they don’t require specialized forming tools. - Not suitable for pressured use; thicker material and reinforcement are needed to prevent sagging. **Applications:** - Good for atmospheric pressure storage or holding tanks. - Useful when a lower head height is required.#6. Simple Flanged Tank Heads

**Characteristics:** - Similar to flat heads but include a formed straight flange around the perimeter. - Not suitable for pressured use and require specific forming equipment. **Applications:** - Suitable for atmospheric pressure storage or holding tanks. - Useful when a lower head height is desired.#7. Hemispherical Tank Heads

**Characteristics:** - Half-spherical shape with an overall height equal to half the diameter. - Offers minimal thickness but is made from welded pieces, making it more expensive. **Applications:** - Used on large-diameter tanks or high-pressure applications to reduce material and weight. - Two hemispherical heads can form a storage sphere, the most efficient shape for high-pressure storage.Conclusion

With decades of expertise in manufacturing safe, high-quality tanks, T BAILEY, INC. adheres to ASME, API, AWWA, and UL standards. We’re here to assist you in selecting the ideal tank head for your needs. If you need guidance, our team is ready to provide professional, detailed advice tailored to your situation.Flat Steel,Steel Flat Bar,Flat Stock Steel,Flat Metal Strips

Huaibei Zhonglian Steel Technology Co., Ltd. , https://www.zlxgsteel.com