For centuries, shackles have been indispensable in securing and lifting heavy objects. These U- or O-shaped metal connectors are the backbone of the lifting, rigging, and towing industries. However, with great strength comes great responsibility. Using the wrong shackle or exceeding its capacity can result in severe consequences. This guide aims to equip you with the knowledge to select the appropriate shackle for the task at hand and ensure safe and efficient operations.

Understanding the Anatomy of a Shackle

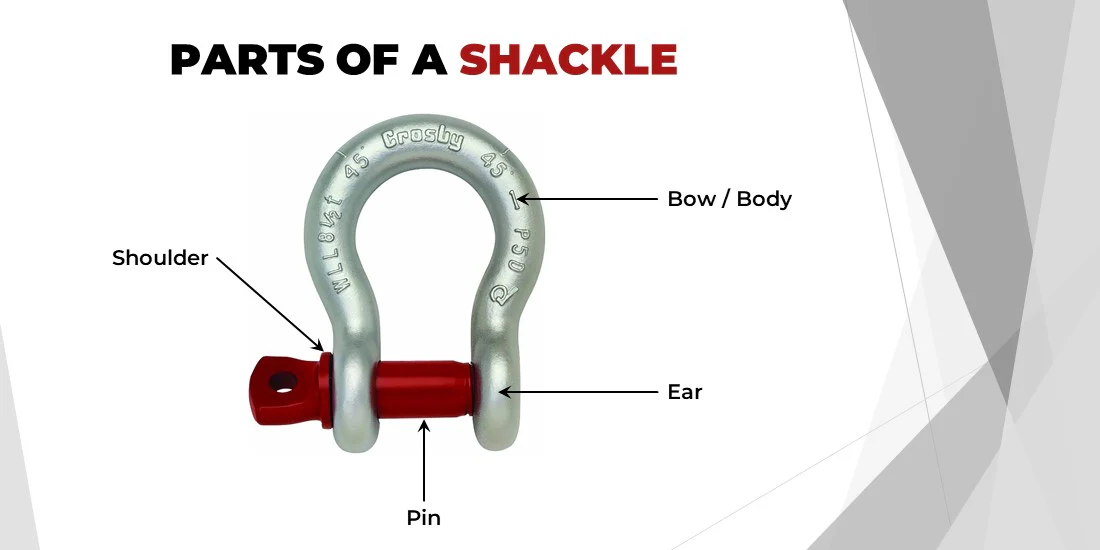

A typical shackle comprises several key components:

Body (also called bail or dee): The main U- or O-shaped component providing overall structure and strength.

Ears: The openings on either side of the body where the pin fits through.

Pin: The removable metal rod securing the opening. Pin types vary depending on the shackle design (screw pin, bolt type, round pin). We'll explore these later.

Shoulder: The reinforced area where the pin meets the body, designed to handle pulling forces.

Beyond Basic Shapes: A World of Options

While U-shaped and D-shaped shackles are common, the shackle world offers much more variety:

Wide Body Shackles: Designed with an extra-wide opening to accommodate thicker wires, ropes, or multiple slings.

Long Reach Shackles: These have an elongated body for added clearance between the shackle and the lifting point. Useful for bulky objects or limited space.

Specialized Shackles: Going Beyond the Basics

An anchor or chain shackle might be your go-to choice for many towing situations, but there are times when a more specialized tool is necessary. Let’s explore some of the essential specialized shackles that can enhance your towing and recovery operations:

Synthetic Sling Shackles

Problem:Â Â Standard shackles can pinch or bunch synthetic slings, reducing their WLL and potentially damaging the sling fibers.

Solution:Â Â Synthetic sling shackles boast a wider bow specifically designed to accommodate synthetic web slings or roundslings. This wider opening allows the sling to sit flat, preventing bunching and ensuring the sling utilizes its full rated capacity (WLL).

Benefits:Â

Maximizes the WLL of synthetic slings.

Reduces wear and tear on the sling.

Available in screw pin or bolt type for secure fastening.

Wide Body Shackles

Applications:Â Â Ideal for use with high-capacity synthetic slings, roundslings, or even wire rope slings.

Important Note:Â Â When using a wide body shackle with wire rope, ensure the shackle's inner diameter is equal to or greater than the wire rope diameter.

Benefits:Â

Increased surface area for the sling to bear on, resulting in a better  D/d ratio  (diameter of the pin to diameter of the wire rope/sling). This translates to improved service life for the sling.

Eliminates the need for a thimble eye on the wire rope sling.

Prevents kinking and bunching of the sling around the bow, reducing wear and tear.

Long Reach Shackles

Applications:Â Â Perfect for construction scenarios where a longer reach is required to connect to specific pick points. They can also be used as a bail for lifting bulky objects.

Benefits:Â

- Extended reach allows for easier connection to lifting points in tight spaces or with obstacles in the way.

- Can function as a lifting bail for objects with wide clearances.

Sheet Pile Shackles

Applications:Â Â Designed specifically for pulling sheet piles (interlocking walls) in construction or marine environments.

Unique Feature:Â Â These shackles often come with an easy-opening pin that remains captive (attached to the shackle body). This prevents accidental detachment and loss of the pin during operation.

By understanding these specialized shackle options, you can select the right tool for the job, ensuring efficient, safe, and damage-free towing and recovery operations.

Choosing the Right Material for Your Shackle

The material you choose for your shackle depends on several factors:

Working Load Limit (WLL):Â Â The material's inherent strength must safely handle the intended load.

Application Environment:Â Â Consider corrosion resistance needs (e Hastelloy Material,Hastelloy Tubing,Hastelloy C22 Round Bar,Hastelloy C276 Pipe Shaanxi Jiade Import And Export Co., Ltd , https://www.jdsteeltube.com