â€

Enhancing Methanex Titan Cooling Tower: A Sustainable Reinforcement Solution

Methanex is a global leader in methanol production, known for its dedication to operational excellence and adherence to industry best practices. The company prides itself on quickly addressing any issues within its facilities, ensuring that everything runs smoothly and meets the highest standards. The Methanex Titan Cooling Tower, situated in the Caribbean, is a massive structure built with reinforced concrete, designed to endure harsh environmental conditions.

Addressing Structural Integrity at Methanex Caribbean Plant

The Methanex facility in the Caribbean recently underwent a major structural reinforcement project. The first phase focused on a 10' x 50' section of the western wall of the cooling tower, where significant spalling and concrete degradation had occurred. This damage was caused by saltwater intrusion, which led to corrosion of the internal steel reinforcements. As the steel expanded, it caused further cracking and spalling, exposing more rebar and accelerating the deterioration process. To determine the most effective repair strategy, HJ3 conducted a thorough inspection to identify critical areas needing immediate attention.

Empowering Structural Resilience: Phase One and Two Repairs

In the second phase of the project, HJ3 expanded the repairs to include 15 support columns on both the North and South walls of the cooling tower. These columns had suffered from chemical exposure and weather-related damage. The assessment revealed high-priority exposed rebar and structural cracks. Replacing these columns entirely would have been costly and time-consuming, leading to significant downtime and increased expenses.

Swift and Efficient Repairs: Savings and Sustainability

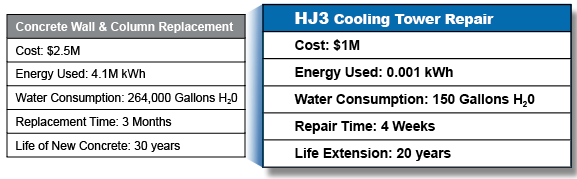

Remarkably, HJ3 completed both phases of the project within four weeks, delivering substantial cost savings—approximately 50% less than what a full replacement would have cost. This not only saved money but also minimized production disruption, allowing Methanex to continue operating efficiently without major interruptions.

Restoring Structural Integrity: How It Was Done

During phase one, HJ3 used CarbonSeal carbon fiber reinforcement to restore the 10' x 50' section of the west wall, bringing it back to its original strength. Given the extent of the damage, preventing future corrosion of the steel reinforcement was a top priority. In phase two, the team focused on reinforcing 15 columns on the North and South walls, which had visible rebar and structural cracks. By implementing a dual 12-hour shift schedule, HJ3 managed to complete each phase in just two weeks.

HJ3's Innovative Reinforcement Process

For both phases, the concrete surfaces were carefully prepared according to HJ3’s strict specifications. After cleaning and priming with HJ3’s specialized primer, exposed rebar received a zinc coating to prevent flash rusting. A high modulus paste was applied, followed by the CarbonSeal carbon fiber system, which was fully saturated and adhered to the surface. A final layer of high modulus paste and two topcoats were added to ensure long-term durability. For phase two, brace plates were used to prevent post-cure curling of the carbon fiber fabric.

Sustainability and Cost-Effectiveness: The Results

By proactively reinforcing the cooling tower, Methanex avoided the need for a full replacement. This decision not only extended the life of the structure by an estimated 20 years but also significantly reduced environmental impact. Compared to a full replacement, the project prevented five tons of concrete and steel waste, nearly 30,000 tons of CO2 emissions, 4 million kWh of energy use, and almost 264,000 gallons of water. Additionally, HJ3’s solution provided a 50% cost saving over traditional replacement methods. This intervention helped Methanex avoid a potential production shutdown that would have occurred within a year if no action had been taken.

Elevate the Structural Integrity of Your Facilities

If you're concerned about the structural health of your cooling towers or want to learn more about HJ3's carbon fiber reinforcement solutions, contact our expert project managers today. They can help you explore sustainable, cost-effective ways to extend the life of your infrastructure and ensure long-term reliability.

â€

â€

Bimetallic Screw And Barrel,Ni-Based Alloy Barrel,Bimetallic Barrel,Alloy Screw And Barrel

Zhejiang Guangming Plastics Machinery Co.,Ltd. , https://www.gmscrews.com