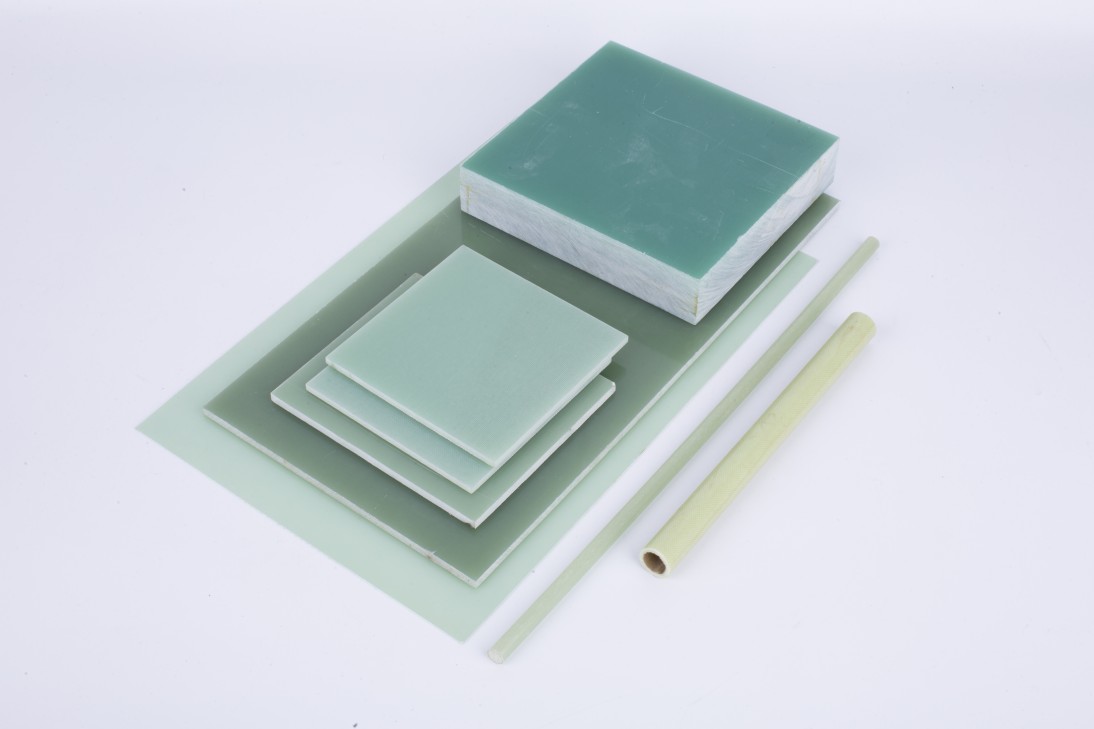

FR4 G10 Epoxy Fiber Glass Parts HONY®FR4 is a NEMA grade designation for glass-reinforced epoxy laminate material. FR-4 is a composite material composed of woven fiber cloth with an epoxy resin binder that is flame resistant (self-extinguishing). "FR" stands for "flame retardant", and does not denote that the material complies with the standard UL94V-0 unless testing is performed to UL 94, Vertical Flame testing in Section 8 at a compliant lab. The designation FR-4 was created by NEMA in 1968. FR-4 glass epoxy is a popular and versatile high-pressure thermoset plastic laminate grade with good strength to weight ratios. With near zero water absorption, FR-4 is most commonly used as an electrical insulator possessing considerable mechanical strength. The material is known to retain its high mechanical values and electrical insulating qualities in both dry and humid conditions. These attributes, along with good fabrication characteristics, lend utility to this grade for a wide variety of electrical and mechanical applications. Grade designations for glass epoxy laminates are: G-10 ,G-11, FR-4, FR-5 and FR-6. Of these, FR-4 is the grade most widely in use today. G-10, the predecessor to FR-4, lacks FR-4's self-extinguishing flammability characteristics. Hence, FR-4 has replaced G-10 in most applications. FR-4 epoxy resin systems typically employ bromine, a halogen, to facilitate flame-resistant properties in FR-4 glass epoxy laminates. Some applications where thermal destruction of the material is a desirable trait will still use G-10 non flame resistant. G10 FR4 glass epoxy laminate Grade: G10/G11 Fiber Reinforced Composite Colour: Sheets are supplied in green Thickness: 0.80mm to 35mm Subcategory: Epoxy; Filled/Reinforced Thermoset; Polymer; Thermoset G10 FR4 glass epoxy laminate Description: Fr4 G10 Glass Epoxy Cutting Board is specified for its extremely high strength and high dimensional stability over temperature. G-11 is used for terminal boards, high humidity applications, electrical and electronic test equipment and electric rotor insulation. G-11 is difficult to cut or machine and may require special equipment. G-10 is slightly Stronger while G-11 is a better insulator and can withstand higher temperature G-11 and similar fibreglass reinforced thermosets are sometimes known as Garolite. HONY Plastic is an industry leader in FR4 and G10 machining. We are able to maintain tolerances, create features and produce parts that even the material manufacturers deem unobtainable. By using high speed spindles capable of turning at 30,000 RPM, tightly controlled work envelopes and cutting edge work holding systems, HONY Plastic can machine components from the most simple part to the most intricate part on any of the 35 machines in our facility. 27" x 15" x 13" Work Envelope Tolerances to +/- .00025" (0.006 mm) Hole Diameters to 0.003" (0.076 mm) Fiber Glass PCB board,Fr4 G10 washer spacer glasket,G10 FR4 glass epoxy laminate,FR4,G10,FR4 G10 Insulation Gasket Epoxy Fiber Glass,Wave soldering jig SMT jig FR4 Hony Engineering Plastics Limited , https://www.honyplastic.com1. Specifications

Product Name

Brass Shell for Connectors

Material Options

Stainless Steel (SS304, SS316), Aluminum (Al6061, Al6063), Brass (C36000, C37700, C38500), Copper, Bronze, etc.

Surface Finish

Polishing, Sandblasting, Passivation, Electroplating, Anodizing, Powder Coating, and more.

Size Range

Standard sizes available or custom-made based on drawings or samples (0-800mm).

Tolerance

+/- 0.01mm

Quality Control

All products undergo 100% inspection by OQC before shipping.

Sample Policy

Free samples available if in stock; charged samples may apply for custom production.

Packaging

Standard export cartons with pallets or customized packaging as per client requirements.

Production Capacity

Up to 50,000 pieces per day.

Lead Time

Typically 3–7 working days depending on order size and complexity.

After-Sales Service

We provide full support after delivery and will resolve any issues promptly.

Payment Terms

T/T, L/C, PayPal, Western Union, and other secure payment methods.

2. Product Photo Show

3. Application Fields

4. Production Show

5. Inspection

6. Packing & Delivery

7. FAQ

1. How to Place an Order?

* Send us your drawing or sample with details such as material, surface treatment, quantity, and special requirements.

* We will produce a sample and send it to you for approval.

* Once the sample is approved, place an order and pay a 30% deposit.

* We begin production upon receiving the deposit.

* After completion, we will take photos for your confirmation, and then you pay the remaining balance.

* Finally, we ship the goods via courier.

2. How long to get a quotation?

We will provide a quotation within 8 hours, considering time differences.

3. How to get a sample?

We can provide free samples if available or charge for custom samples.

4. How long does production take?

Usually 10 working days. The schedule depends on order quantity and delivery needs.

5. What are the payment terms?

For small orders, we accept Western Union or PayPal. For larger amounts, T/T is preferred.

6. How about shipping?

Samples are sent by air if not too heavy; otherwise, sea or air freight is used.

7. What if the product is not good?

Contact us immediately. Our dedicated after-sales team will handle the issue promptly.

CONTACT US:

Vivi Zhao – Sales Manager

Mobile: +86 13967666271

Address: Xinzhu Park, Dongcheng Street, Yongkang City, Zhejiang, China.

Website: www.honcho.cc